Soluções permanentes de engenharia para projetos de grande escala.

A Liderroll é referência no desenvolvimento de soluções permanentes e inovadoras para projetos de engenharia complexos.

Em breve, um site novo!

Dias

Horas

Minutos

Segundos

Liderroll Indústria e Comércio de Suportes Especiais LTDA, a company that holds a prominent position among the most important engineering and construction firms in Brazil, has built an extensive portfolio of completed projects and maintains a strong presence in the oil and gas sector. Our history has been marked by our ability to innovate, take risks, and pioneer new technologies, as well as by the implementation of differentiated and innovative solutions.

We have a team of highly experienced professionals in the fields of engineering, project development, pipeline and gas pipeline construction, industrial assembly, and self-supporting structures, with significant relevance in the national market, particularly for Petrobras. All our teams are highly qualified to deliver excellence, being authorized and registered in the oil and gas sector as a company with the capacity to undertake EPC (Engineering, Procurement, and Construction) projects.

LIDERROLL, a 100% Brazilian engineering solutions company, was founded in 2007, headquartered in the municipality of Duque de Caxias, near the largest and most complex refinery in Brazil, with offices in Rio de Janeiro and Houston, USA – considered the world capital of oil. The company develops pipeline projects, manufactures special large-diameter supports (38” to 104”), and executes installation, construction, and assembly works in the oil and gas market.

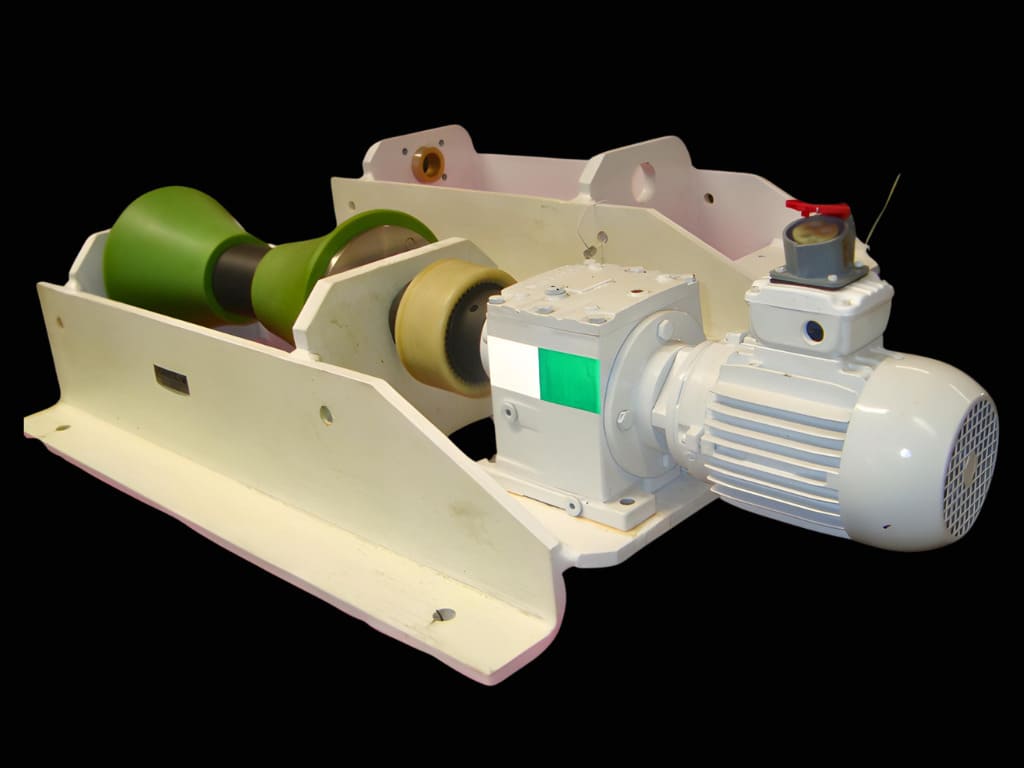

Since its foundation, LIDERROLL has gained international recognition through the design and development of free-spinning high-performance plastic rollers (RPAP), motorized rollers (RMOPAP), and the Exoway system for pipeline installation on slopes, capable of overcoming angles from 5° up to 90°.

We develop and patent products that solve complex challenges in the pipeline sector, ensuring high performance and durability in every project.

Our teams specialize in the construction and assembly of pipelines in challenging environments, such as tunnels and trenches, applying methods that reduce both costs and execution time.

Liderroll adopts practices that minimize environmental impact and ensure worker safety at every stage of the project, in full compliance with the highest QHSE standards.

Liderroll operates as a construction and assembly company, delivering integrated solutions for pipeline, ductwork, and industrial installation projects.

Our differential lies in mastering construction methods that eliminate logistical bottlenecks and significantly shorten delivery times.

We operate with high efficiency in confined environments such as tunnels and trenches, applying advanced technologies that eliminate safety risks and reduce costs.

Our portfolio includes highly complex projects such as the Caraguatatuba-Taubaté Gas Pipeline (GASTAU) and the Gasduc III Tunnel, where we implemented exclusive pipeline handling systems, minimizing environmental impact and increasing operational productivity.

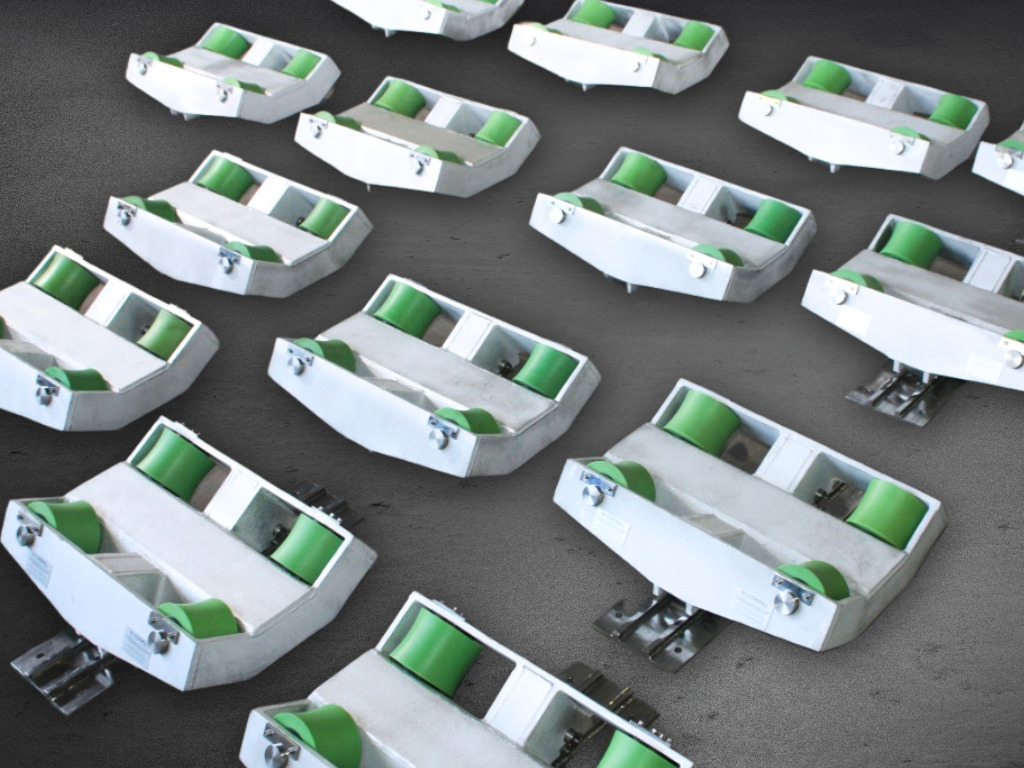

In the TAIC Project, Liderroll developed an innovative solution to relieve the load on the bridge connecting the Liquefied Petroleum Gas (LPG) terminals at Ilha Comprida and Ilha Redonda, located in Guanabara Bay, Rio de Janeiro. The company designed and supplied high-performance plastic bidirectional rollers, allowing the pipelines to move both frontally and laterally—an essential solution for expanding the LPG lines without overloading the bridge’s concrete structure.

Liderroll manufactured 430 rollers, 90 of which were bidirectional, in record time, with the factory operating in three shifts to meet Petrobras’ deadline. This innovative technical solution was the first of its kind to be marketed globally, highlighting Liderroll’s ability to respond efficiently and creatively to engineering challenges.

The Gasduc III Tunnel is a milestone in pipeline engineering in Brazil, extending 3,758 meters with high technical complexity. Using Liderroll’s exclusive Motorized Roller technology, nearly four kilometers of pipelines were installed inside the tunnel under the Serra dos Gaviões in just 26 days. This innovative solution replaced conventional methods that would have taken months, generating significant cost savings for Petrobras and drastically reducing operational risk.

Moreover, the tunnel project preserved 125,400 m² of Atlantic Forest and protected endangered species such as the golden lion tamarin, while the excavated material was reused in degraded areas. Gasduc III, totaling 179 km, increases natural gas transportation capacity to Southeastern Brazil, ensuring supply for power plants serving millions of residents.

The Caraguatatuba-Taubaté Gas Pipeline (GASTAU), spanning 96 km, was designed to transport natural gas from the Mexilhão field in Caraguatatuba to the REVAP Refinery in São José dos Campos. Liderroll played a key role in the project’s success by developing an innovative methodology for installing pipelines inside a 5,120-meter tunnel in the Serra do Mar. Facing challenging conditions such as limited space and high logistical complexity, Liderroll applied its Motorized Roller technology, allowing autonomous pipe movement without the need for cranes or welding inside the tunnel.

The project avoided significant environmental impacts, preserving the Atlantic Forest, and was completed in record time with high safety and efficiency, demonstrating Liderroll’s ability to overcome technical challenges in large-scale projects of strategic importance for Brazil’s energy sector.

The OCVAP I and II Projects, developed by Liderroll for Petrobras, involved the simultaneous installation of two 8-inch pipeline lines inside the GASTAU tunnel, connecting the Caraguatatuba treatment unit to the REVAP Refinery in São José dos Campos. Liderroll was responsible for the full engineering scope, including the construction of work yards, ventilation, lighting, and mechanical support assembly.

Due to the confined environment and technical complexity, Liderroll’s expertise was crucial to ensure safe and efficient execution without interrupting GASTAU pipeline operations. Completed in 600 days without accidents and on schedule, the project was rated excellent by Petrobras, reaffirming Liderroll’s ability to handle highly complex engineering challenges.

At Liderroll, compliance with the industry’s best practices and adherence to international quality standards are top priorities.

Our Quality, Health, Safety, and Environmental (QHSE) policy is applied across all levels of the organization, ensuring the integrity of our processes and the well-being of our employees.

In addition, we provide our Code of Ethics and Conduct, which sets forth the ethical behavior guidelines for all institutional and business activities.

In some industries, devices used to support, guide, or roll pipes during installation or operation consist of steel rollers with bearings/bushings or welded supports attached to the pipe, featuring sliding Teflon®/Celeron bases. In addition to requiring constant maintenance such as surface cleaning (stainless steel plates), lubrication (bearings), and corrosion treatment (painting), they also demand frequent replacement of defective bearings and worn Teflon/Celeron inserts. These needs generate high direct costs for maintenance services, as well as indirect costs due to operational downtime during component replacement.

Liderroll’s expertise in manufacturing special plastic rollers for offshore pipelines enabled Petrobras to innovate by contracting our company to design and produce plastic rollers for the Stinger installed on the BGL 1 Barge. The contract was signed in January 2009, and all components were delivered in July of the same year — just six months later. A total of 52 rollers, each with a 36 cm diameter, were installed on the long-range Stinger — equipment that assists in pipeline laying — mounted on the vessel.